Printashrink SPF

Actions

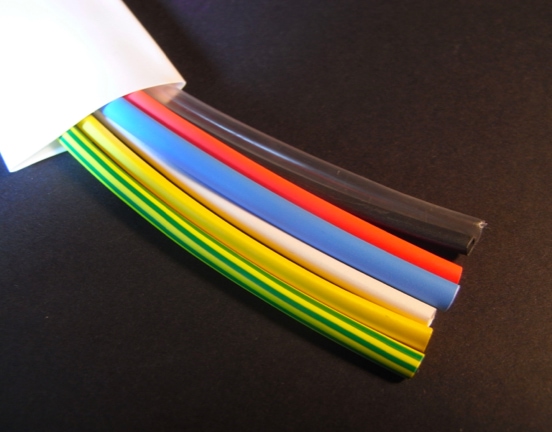

Printashrink SPF is a 2:1 shrink ratio heatshrink polyolefin with a working temperature of 135°C. It is a UL approved, fire retardant sleeve which meets MIL-SPEC requirements making it perfect for aerospace, military, defence and other professional applications. It is available in many colours and sizes up to 101.6mm ID and can be cut and printed as required.

This flexible, 2:1 heatshrink tube is ideal for a wide range of applications where MIL-SPEC and/or UL approval is necessary or favourable. It is used in many industries including military/defence, aerospace, electrical, electronic and automotive sectors and is valued for its insulation, mechanical protection and strain relief properties. Its smooth, regular surface and availability in many colours and sizes also makes it perfect for printing both text and logos. We offer our full range of printing and cutting services on this high strength, resilient tube making it perfect for branding and marking requirements

Technical Data

- Shrink Ratio: 2:1

- Shrink Temperature: >90°C

- Operating Temperature: -55°C - +135°C

- Flame Retardant: Yes (except clear)

- Colours:

- Black,

- Red,

- Yellow,

- Blue,

- White,

- Clear,

- Other colours available upon request

- Sizes: 1.2 - 101.6

- Packing: Reels, mini-reels, mini-packs, cut to length, kits, cut sleeves

- Print: Yes, full range of text and logos in all colours

- Approvals: AMS-DTL-23053/5 Cl 1, 2 & 3, UL certified, CSA certified, Def Stan 59-97 Type 2b, VG 95343 Pt5 Type A+B, VDE 0341 Pt9005, BS 4G-198 Pt3 11B, RoHS compliant

- Applications / Industries:

| Properties | Typical Values | Test Methods |

|---|---|---|

| General | ||

| Operating Temperature | -55°C - +135°C | |

| Full recovery temperature | 120°C | |

| Shrink temperature | >90°C | |

| Shrink Ratio | 2:1 | |

| Physical | ||

| Longitudinal change | +5% -5% | |

| Thermal | ||

| Flammability | Pass (except clr) | ASTM D2671 |

| Heat shock (4hrs) | No dripping, cracking or flowing | |

| Low temperature flexibility (4hrs @ -55°C) | No cracking | |

| Heat ageing (168hrs) | @ 175°C, no dripping, cracking or flowing | |

| Electrical | ||

| Dielectric strength | 20kV/mm min | |

| Chemical | ||

| Fluid resistance | At 23°C for 24hrs, aircraft fuel, phosphate ester based, lubricating oil ester based | ISO1871 Test liquids B, 103, 101 |

Free Artwork service

As part of the fully comprehensive print process, we offer a free artwork service.

Enquire Now

Cable Identification Service

We offer a complete service based on our many years of experience and development in this highly specialised field.

Enquire Now